แมกนีเซียมออกไซด์, a seemingly ordinary inorganic compound, plays an indispensable role in numerous industries by virtue of its unique physical and chemical properties. It is not only an important raw material in industrial production but also plays a key role in agriculture, ยา, environmental protection and other fields, becoming a “versatile assistant” promoting the development of various industries.

Refractory Materials Industry: อัน “Solid Shield” Under High Temperature

In the refractory materials industry, magnesium oxide is undoubtedly the core raw material. With a melting point as high as 2800°C, it can maintain stable physical form and chemical properties in extreme high-temperature environments, building a solid protective barrier for various high-temperature equipment.

In steel smelting, magnesium oxide is often used to manufacture refractory linings for equipment such as converters, electric furnaces, and ladles. These equipments need to withstand high temperatures above 1600°C during steelmaking, as well as severe scouring and erosion from molten steel and slag. Refractory bricks or coatings made of magnesium oxide, relying on their excellent slag resistance and high-temperature resistance, can effectively extend the service life of the equipment and ensure the continuous and stable progress of steelmaking production. ตัวอย่างเช่น, MgO-C refractories, by reasonably combining magnesium oxide and graphite, not only retain the high-temperature resistance of magnesium oxide but also improve the material’s ability to adapt to sudden temperature changes with the help of the lubricity and thermal shock resistance of graphite, which are widely used in modern steelmaking processes.

In high-temperature kilns in industries such as glass and cement, magnesium oxide also plays a significant role. The working temperature of glass melting furnaces is usually around 1500°C, and magnesium oxide refractories can resist the erosion of glass melt and ensure the normal operation of the furnace; when cement rotary kilns calcine cement clinker, the temperature is as high as 1450°C, and magnesium oxide-based refractories can withstand the friction and high-temperature effects of materials in the kiln, reducing equipment maintenance times and improving production efficiency.

Construction Industry: An “Optimization Master” of Material Performance

The construction industry is another major application field of magnesium oxide, which can optimize the performance of building materials in various ways and improve the quality and safety of construction projects.

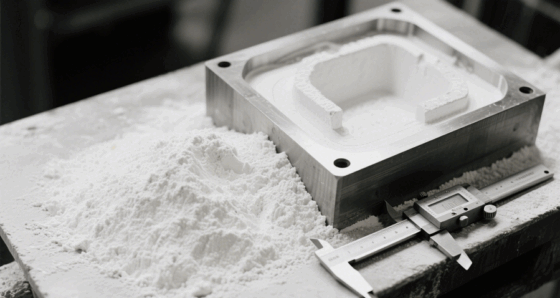

In magnesium-based building materials, magnesium oxide is a key raw material for the production of magnesite products. Mixing magnesium oxide with magnesium chloride solution in a certain proportion can form magnesium cement with good gelling properties, and then produce magnesite boards, magnesite manhole covers, magnesite greenhouse brackets and other products. These magnesite products have the advantages of high strength, good fire resistance, thermal insulation, corrosion resistance, เป็นต้น, and the production process has low energy consumption and little pollution, which conforms to the development concept of green buildings. ตัวอย่างเช่น, as a new type of wall material, magnesite boards can not only meet the load-bearing requirements of buildings but also effectively block the spread of fire, and are increasingly used in the decoration of high-rise buildings and public places.

In concrete production, magnesium oxide can also play an important role. Adding an appropriate amount of magnesium oxide can adjust the setting time of concrete and improve its working performance. ในเวลาเดียวกัน, the products generated by the reaction of magnesium oxide with certain components in concrete can fill the pores inside the concrete, improve the compactness and strength of concrete, enhance its impermeability and durability, and prolong the service life of buildings.

Chemical Industry: อัน “Capable Assistant” in Chemical Reactions

In the chemical industry, the application of magnesium oxide is ubiquitous. It is not only a catalyst or co-catalyst for many chemical reactions but also an important raw material for the production of other chemical products.

In the field of catalysts, magnesium oxide is often used as a catalyst carrier or directly as a catalyst because of its high specific surface area and surface activity. ตัวอย่างเช่น, in the synthetic ammonia industry, magnesium oxide can be used as an auxiliary agent of the catalyst to improve the activity and stability of the catalyst and promote the synthesis reaction of ammonia; in the hydrogenation reaction of petrochemical industry, magnesium oxide can enhance the anti-poisoning ability of the catalyst and extend the service life of the catalyst.

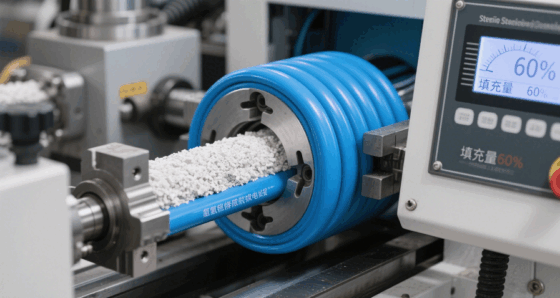

In the production of inorganic chemical products, magnesium oxide is the main raw material for preparing magnesium sulfate, magnesium oxide whiskers, magnesium hydroxide and other products. Magnesium sulfate has a wide range of uses in medicine, agriculture and other fields; magnesium oxide whiskers have excellent mechanical properties and high-temperature resistance and can be used as reinforcing agents for composite materials; magnesium hydroxide is an important inorganic flame retardant, and its production is inseparable from magnesium oxide. In addition, magnesium oxide can also be used to prepare ceramic materials, electronic materials, เป็นต้น, providing strong support for the development of new chemical materials.

Pharmaceutical Industry: An “Invisible Guardian” for Health Protection

Although the application of magnesium oxide in the pharmaceutical industry is not well known, it plays an important role in protecting human health.

Medicinal magnesium oxide is a common antacid and laxative. เป็นยาแก้ท้องเฟ้อ, it can neutralize gastric acid, relieve stomach pain, heartburn and other symptoms caused by excessive gastric acid, and its effect is mild and long-lasting; as a laxative, magnesium oxide reacts with water in the intestine to form magnesium hydroxide after oral administration, which stimulates intestinal peristalsis and promotes defecation, and can be used to treat constipation. In addition, magnesium oxide is also used as an auxiliary material in some compound medicines, which helps in the formation and stability of medicines.

In the field of medical devices, magnesium oxide can be used to prepare bioceramic materials. ตัวอย่างเช่น, magnesium oxide-based bioceramics have good biocompatibility and degradability, and can be implanted into the human body as bone repair materials, which are gradually absorbed and replaced by human tissues, realizing the regeneration and repair of bone tissue, and providing a new way for the treatment of orthopedic diseases.

Agricultural Industry: อัน “Nutrition Supply Station” for Crop Growth

In agricultural production, magnesium oxide is one of the indispensable nutrient elements for crop growth, which is of great significance for improving crop yield and quality.

Magnesium is a component of plant chlorophyll and participates in plant photosynthesis. When the content of magnesium in the soil is insufficient, crops will have problems such as yellow leaves, slow growth, and reduced yield. At this time, applying magnesium oxide fertilizer can supplement the magnesium content in the soil, promote the synthesis of chlorophyll, enhance the photosynthesis of crops, and improve the yield and quality of crops. Magnesium oxide fertilizer is suitable for a variety of crops, such as rice, wheat, corn, vegetables, fruits, เป็นต้น, and is especially effective for magnesium-loving crops such as potatoes and grapes.

In addition, magnesium oxide can also be used to adjust soil pH. For acidic soil, applying an appropriate amount of magnesium oxide can neutralize soil acidity, improve soil structure, increase soil fertility, and create a good soil environment for crop growth. ในเวลาเดียวกัน, magnesium oxide also has a certain bactericidal effect, which can reduce harmful microorganisms in the soil and reduce the occurrence of crop diseases and insect pests.

Environmental Protection Industry: An “Efficient Weapon” for Pollution Control

With the increasing awareness of environmental protection, the application of magnesium oxide in the environmental protection industry has also received increasing attention, becoming an “efficient weapon” for pollution control.

ในการบำบัดน้ำเสีย, magnesium oxide can be used to remove heavy metal ions, fluoride ions and other pollutants in wastewater. Magnesium hydroxide generated by the reaction of magnesium oxide with water has strong adsorption capacity, which can chemically react with heavy metal ions in wastewater to form precipitates, thereby removing heavy metal ions from water; for fluorine-containing wastewater, magnesium oxide can combine with fluoride ions to form insoluble magnesium fluoride precipitates, achieving the purpose of fluorine removal. Compared with other water treatment agents, magnesium oxide has the advantages of good treatment effect, low cost and no secondary pollution.

In the field of flue gas desulfurization, magnesium oxide desulfurization technology is an efficient and economical desulfurization method. Magnesium oxide reacts with sulfur dioxide in flue gas to form magnesium sulfite and magnesium sulfate, thereby removing sulfur dioxide from flue gas. This technology has a high desulfurization efficiency, up to more than 95%, และผลพลอยได้สามารถรีไซเคิลได้, realizing the recycling of resources, which is in line with the requirements of environmental protection and sustainable development.

The application of magnesium oxide is far more than that, and it can also be seen in industries such as aerospace, electronics, and metallurgy. With the continuous progress of science and technology, the performance of magnesium oxide will be further optimized, and its application fields will continue to expand, continuing to contribute to the development of various industries and becoming a veritable “versatile assistant”.

Magnesium oxide_magnesium hydroxide_magnesium carbonate ผู้ผลิตกลุ่ม-Zehui

Magnesium oxide_magnesium hydroxide_magnesium carbonate ผู้ผลิตกลุ่ม-Zehui