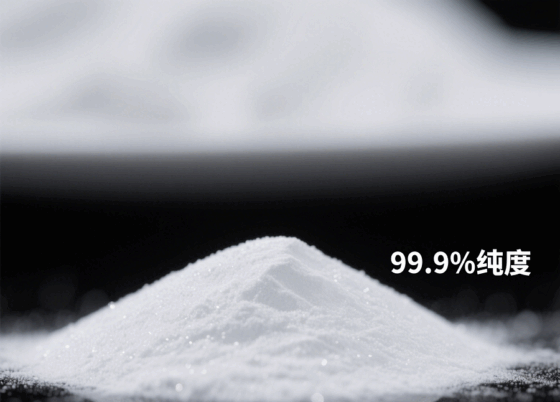

Óxido de magnésio, with its unique chemical properties and physical characteristics, occupies an important position in the field of building materials. It can not only improve key properties of building materials such as strength, resistência ao fogo, and corrosion resistance but also promote the development of green and environmentally friendly building materials. From wall materials to decorative materials, from fire – resistant products to floor materials, magnesium oxide can be found in various building material products.

Aplicações amplamente utilizadas de óxido de magnésio em produtos de materiais de construção

Magnesite Series Wall Materials

Magnesite series wall materials are one of the most widely used product categories of magnesium oxide in the construction field. They are made with magnesium oxide and magnesium chloride as the main cementing materials, combined with fillers such as straw and sawdust, and have many excellent characteristics.

Magnesite board is a typical representative of magnesite series wall materials. According to different usage scenarios and performance requirements, it can be divided into ordinary magnesite boards, fire – resistant magnesite boards, waterproof magnesite boards, etc.. Ordinary magnesite boards have high strength and light weight, with a flexural strength of more than 15MPa, which can meet the load – bearing requirements of walls and are often used in indoor partitions, ceilings and other parts; fire – resistant magnesite boards, relying on the non – combustible property of magnesium oxide, have a fire resistance rating of Class A, which is essential in the decoration of crowded places such as shopping malls, hotels and hospitals. Even in case of fire, they can effectively delay the spread of fire and buy time for personnel evacuation; waterproof magnesite boards, through special treatment processes, have improved water resistance and can be used for wall decoration in humid environments such as bathrooms and kitchens, avoiding the problem that traditional wall materials are prone to mildew and deformation in humid environments.

In addition to magnesite boards, magnesite composite wall panels are also common wall materials. They are composed of two layers of magnesite boards with insulation materials in the middle, and have multiple functions such as load – bearing, thermal insulation and fire resistance. This kind of composite wall panel is easy to install, has high construction efficiency, can greatly shorten the construction period, and is widely used in prefabricated buildings.

Fire – Resistant Building Products

With the increasing emphasis on building fire safety, the application of magnesium oxide in fire – resistant building products is becoming more and more important, and its excellent flame – retardant performance guarantees building safety.

Magnesite fire doors are a typical application of magnesium oxide fire – resistant products. They use magnesite boards as the base material of door panels and are filled with fire – resistant and thermal insulation materials inside, having good fire resistance and thermal insulation performance. According to relevant standards, the fire resistance limit of Class A magnesite fire doors is not less than 1.5 hours, Class B not less than 1 hour, and Class C not less than 0.5 hours. They can effectively block the transmission of flames and high temperatures in case of fire, buying time for personnel escape and property protection. Ao mesmo tempo, magnesite fire doors also have good sound insulation effect and mechanical strength, meeting the comprehensive needs of building use.

Fire shutter doors are also an important application of magnesium oxide in fire – resistant products. Óxido de magnésio – based fire shutter doors adopt a multi – layer composite structure, among which the magnesium oxide material layer plays a key role in fire resistance. In case of fire, the fire shutter door drops quickly to form a fire barrier to prevent the spread of fire. Compared with traditional steel fire shutter doors, óxido de magnésio – based fire shutter doors are lighter, run more flexibly, and have better fire resistance.

Decorative Materials

Magnesium oxide is also widely used in decorative materials, which can add beauty to buildings while ensuring the performance and quality of materials.

Magnesium oxide decorative boards are one of the commonly used decorative materials. Their surfaces can be treated with veneering, painting, printing, etc., showing rich colors and textures, which can meet the needs of different decoration styles. This kind of decorative board has the characteristics of wear resistance, scrub resistance and anti – aging, and is suitable for decorating indoor walls, ceilings, furniture surfaces, etc.. Por exemplo, in home decoration, using magnesium oxide decorative boards as TV background walls is not only beautiful and elegant but also easy to clean and maintain.

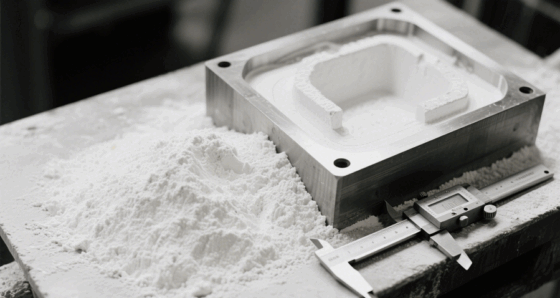

Magnesium art reliefs are application products of magnesium oxide in the high – end decoration field. They are made with magnesium oxide as the main raw material through processes such as mold forming and surface treatment, and have the characteristics of strong three – dimensional sense and rich shapes. Magnesium art reliefs can be used for wall decoration in hotel lobbies, clubs, villas and other places to enhance the artistic atmosphere of the space. Due to the good plasticity of magnesium oxide materials, they can accurately present various complex patterns and details, meeting the creative needs of designers.

Floor Materials

The application of magnesium oxide in floor materials is mainly reflected in products such as magnesium floor tiles and magnesium self – leveling mortar, providing more high – quality choices for floor decoration.

Magnesium floor tiles are made with magnesium oxide and magnesium salt solution as cementing materials, adding aggregates, pigmentos, etc.. They have the characteristics of high strength, high hardness and good wear resistance, with a compressive strength of more than 30MPa, which can bear large loads and are suitable for places with large passenger flow and heavy loads such as shopping malls, warehouses and workshops. Ao mesmo tempo, magnesium floor tiles also have good anti – slip performance and corrosion resistance, and can be used for a long time in humid environments or places with chemical corrosion.

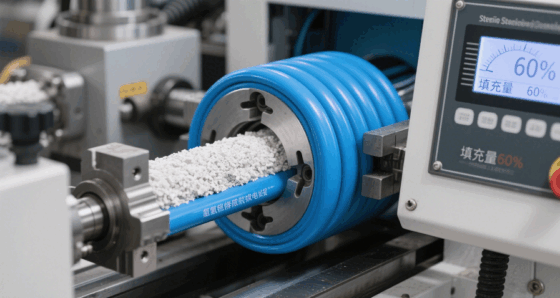

Magnesium self – leveling mortar is a new type of floor material, which is made by mixing magnesium oxide, special cement, aggregates, additives, etc.. It has good fluidity and self – leveling property. During construction, it can flow and level the floor automatically without vibration, forming a flat and smooth surface. After hardening, magnesium self – leveling mortar has high strength, small shrinkage rate and firm bonding with the base, which is suitable for leveling and decorative surface layers of indoor floors. It can be directly paved with wood floors, floor tiles and other decorative materials on it, greatly improving the efficiency and quality of floor construction.

Thermal Insulation Materials

The application of magnesium oxide in thermal insulation materials is mainly through compounding with other thermal insulation materials to form composite thermal insulation materials with both fire resistance and thermal insulation performance.

Magnesium oxide composite insulation boards are made of magnesium oxide boards as the surface layer, with polystyrene foam, rock wool and other insulation materials in the middle. This kind of composite insulation board not only retains the fire resistance of magnesium oxide boards but also has good thermal insulation performance, with a thermal conductivity as low as 0.03W/(m·K) or less. It is suitable for building external wall insulation systems, which can effectively reduce building energy consumption and improve the comfort of indoor living. Ao mesmo tempo, due to its excellent fire resistance, it reduces the fire risk of the external wall insulation system.

Magnesium oxide insulation coating is another thermal insulation product, which is made with magnesium oxide as the base material, adding hollow microspheres, insulation additives, etc.. The coating has good adhesion and workability, and can be directly painted on the surfaces of walls, roofs, etc., to form a thermal insulation layer. Magnesium oxide insulation coating not only has a good insulation effect but also has the characteristics of fire resistance and anti – aging, which can adapt to different climatic environments and prolong the service life of buildings.

To sum up, magnesium oxide is widely used in building material products. It can be seen in various aspects such as walls, floors, decoration, fire protection and thermal insulation. With the continuous improvement of the construction industry’s requirements for material performance and environmental protection, the application prospect of magnesium oxide in the field of building materials will be broader, playing an important role in promoting the green, safe and high – quality development of the construction industry.

Oxido de magnésio_magnésio hidroxide_magnesium carbonato fabricante-zehui Grupo

Oxido de magnésio_magnésio hidroxide_magnesium carbonato fabricante-zehui Grupo