Magnesium hydroxide (Mg(OH)₂) is an important inorganic flame retardant. With its flame-retardant, smoke-suppressant, non-toxic, and environmentally friendly properties, it is widely used in flame-retardant products in various fields. Its flame-retardant mechanism mainly involves decomposing into magnesium oxide and water at high temperatures. The released water can cool the substrate, dilute oxygen and combustible gases, and at the same time, the decomposition product magnesium oxide forms a protective layer to isolate heat and oxygen, thereby achieving the flame-retardant effect. The following are the main product categories in which it is applied in the flame retardant industry:

Products of Magnesium Hydroxide in the Flame Retardant Industry

I. Flame-Retardant Plastic Products

Plastics are flammable, and magnesium hydroxide, as a green flame retardant, is an important choice for flame-retardant modification of plastics, suitable for various plastic varieties:

- Polyolefin products: Such as polyethylene (PE) pipes, films, cable materials, polypropylene (PP) sheets, injection molded parts, etc. In these products, magnesium hydroxide can replace traditional halogenated flame retardants, reducing the release of toxic gases during combustion. It is often used in scenarios with high flame-retardant and environmental protection requirements, such as PE water supply pipes for construction and PP electrical enclosures.

- Engineering plastic products: Including products made of ABS resin, polyamide (PA, nylon), polycarbonate (PC), etc. For example, ABS plastic is widely used in electronic and electrical enclosures. Adding magnesium hydroxide can improve its flame retardant grade to meet the safety standards of electronic equipment; nylon products are widely used in automobile parts and mechanical accessories, and the addition of magnesium hydroxide can enhance their flame resistance.

- Rubber products: Such as cable sheaths, sealing rings, conveyor belts, etc. Rubber itself is flammable, and the addition of magnesium hydroxide can effectively delay its burning speed and reduce smoke generation during combustion. It is especially suitable for fields with strict requirements on flame retardancy and low smoke, such as rubber conveyor belts and cables for mines.

II. Flame-Retardant Wire and Cable Products

Wires and cables may cause fires due to overheating during energization, and magnesium hydroxide is a key material for their flame-retardant treatment:

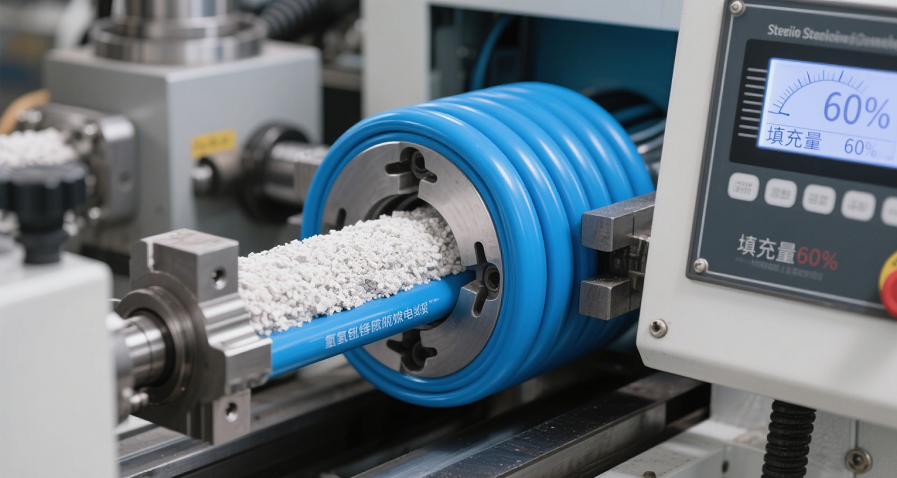

- Flame-retardant cable materials: Adding magnesium hydroxide to the insulation layer and sheath materials of cables can produce low-smoke and halogen-free flame-retardant cable materials. Such cable materials do not release toxic halogen gases when burned and have low smoke concentration, which are suitable for densely populated places or places with extremely high environmental requirements such as high-rise buildings, subways, and nuclear power plants.

- Fire-resistant cables: Magnesium hydroxide is used in the filling layer or wrapping material of some fire-resistant cables, which, together with other fire-resistant materials, can increase the fire resistance time of the cables in fires and ensure the short-term normal operation of key circuits.

III. Flame-Retardant Coating and Coating Products

The flame retardancy of coatings is crucial for the fire protection of substrates. The application of magnesium hydroxide in this field mainly includes:

- Flame-retardant coatings: Adding magnesium hydroxide to water-based or oil-based coatings to make steel structure flame-retardant coatings, wood flame-retardant coatings, etc. For example, steel structure flame-retardant coatings are applied to the surface of building steel structures. In case of fire, magnesium hydroxide decomposes to absorb heat and form a carbonized layer, delaying the heating rate of the steel structure and prolonging its load-bearing time; wood flame-retardant coatings can reduce the flammability of wood and are used for furniture, wooden floors, wooden building components, etc.

- Fabric coatings: Adding magnesium hydroxide to the coating treatment of fabrics such as curtains, carpets, and tents can improve the flame retardant performance of the fabrics, making them meet the corresponding fire safety standards and reducing fire hazards.

IV. Flame-Retardant Building Materials and Thermal Insulation Products

Building materials are the key areas for fire prevention and control, and magnesium hydroxide is widely used in the flame retardancy of building materials:

- Thermal insulation materials: Such as polystyrene foam (EPS), polyurethane foam (PU) and other thermal insulation materials, which are flammable and release toxic gases when burned. After adding magnesium hydroxide, flame-retardant thermal insulation materials can be prepared, which are used in scenarios such as building exterior wall insulation and cold storage insulation to reduce fire risks.

- Fire-resistant panels: In the production of fire-resistant panels such as gypsum boards and fiber cement boards, magnesium hydroxide can be used as a flame-retardant additive to improve the fire resistance limit of the panels, making them suitable for building parts such as fire walls and fire partitions.

- Fire-resistant sealing materials: Adding magnesium hydroxide to fire-resistant sealants, fire-resistant plugging materials and other products can enhance their flame retardant performance, which are used to seal building pipes, cable penetration holes and other parts to prevent the spread of fire and smoke.

V. Other Flame-Retardant Products

- Flame-retardant paper: Adding magnesium hydroxide in the production of packaging paper, wallpaper and other papers can improve the fire resistance of the paper, which is used for packaging flammable items or indoor decoration.

- Flame-retardant adhesives: Adhesives used for bonding electronic components, building materials, etc., can have flame-retardant properties after adding magnesium hydroxide, avoiding the bonding parts from becoming fire hazards.

Summary

As an environmentally friendly flame retardant, magnesium hydroxide plays an important role in flame-retardant products in various fields such as plastics, wires and cables, coatings, and building materials due to its excellent flame-retardant performance and safety. With the increasing environmental protection requirements, the application range of magnesium hydroxide in the flame retardant industry will continue to expand, promoting the emergence of more low-toxic and high-efficiency flame-retardant products.

Magnesium oxide_magnesium hydroxide_magnesium carbonate manufacturer-Zehui Group

Magnesium oxide_magnesium hydroxide_magnesium carbonate manufacturer-Zehui Group